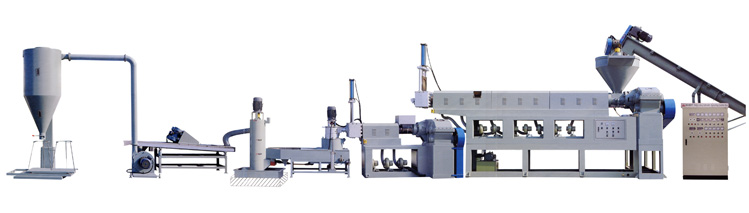

[ Two stages die cutting degassing pelletizer which especially design for PP, PE, PS and other thermoplastic recycling materials. ]

★The desugn is special for PP, PE, PS recycling and other thermoplastics wastes.

| Item | Main Extruder | Secohd extruder | Cooling tank | Dehydrator | Vibrating screener | Centrifugal pellets blower | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification | Screw Dia. | Motor | Temp. control | Output (KG/hr) | Dimesion (M) | Motor | Temp. control | Cutting motor | Dimesion (M) | Water pump | Dimesion (M) | Motor | Dimesion (M) | Motor | Dimesion (M) | Motor |

| Model | ||||||||||||||||

| WJ-GM100 | ψ100mm | 50HP | 6 zones | 100-150 | 4.2x1.8x3.0 | 20HP | 4 zones | 2HP | 2.3x1.5x2.1 | 3HP | 1.8x0.6x0.7 | 7.5HP | 1.3x0.9x2.3 | 0.25kw x2 | 2.8x0.65x1.1 | 3HP |

| WJ-GM120 | ψ120mm | 100HP | 8 zones | 150-250 | 5.1x1.9x3.4 | 30HP | 5 zones | 3HP | 2.9x1.6x2.2 | 3HP | 2.0x0.6x0.7 | 7.5HP | 1.3x0.9x2.3 | 0.25kw x2 | 2.8x0.65x1.1 | 3HP |

| WJ-GM150 | ψ150mm | 150HP | 9 zones | 250-350 | 6.5x2.2x3.7 | 50HP | 5 zones | 5HP | 3.4x1.8x2.4 | 5HP | 2.2x0.65x0.8 | 10HP | 1.35x0.9x2.4 | 0.25kw x2 | 2.8x0.65x1.1 | 5HP |

| WJ-GM175 | ψ175mm | 200HP | 10 zones | 350-450 | 7.2x2.3x3.8 | 75HP | 6 zones | 5HP | 3.7x2.0x2.6 | 5HP | 2.4x0.65x0.8 | 10HP | 1.35x0.9x2.4 | 0.25kw x2 | 2.8x0.65x1.1 | 5HP |

*Specification Subject to change without notice for improvement and modification.

Advantages of die cutting mold (vertical downward extruding model)

- End products are subjected to constant pressure so they are consistent in size and perfectly shaeped.

- Cooling water cover's spray does no moisten the die head so its output is unaffected.

- Downward adjustable colling water cover is easier to operate and replace die cutting.

- The design is special for PP, PE, PS recycling and other thermoplastics wastes.

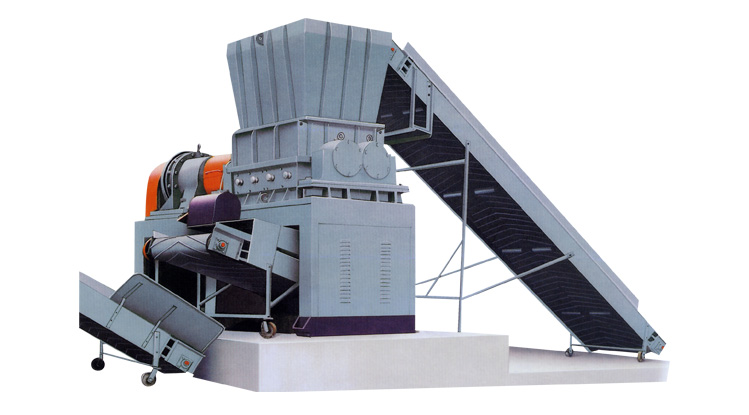

[ SHREDDERS, BREAKERS FOR RUBBER & PLASTICS ]

| Specification | Motor | Cyclo Reducer | Inter Size |

|---|---|---|---|

| Model | |||

| WJ-K 450DC | 30HP | 90# | 450x450 |

| WJ-K 600DC | 40HP | 90# | 600x450 |

| WJ-K 750DC | 50HP | 91# | 750x450 |

| WJ-K 610DC | 50HP | 91# | 610x610 |

| WJ-K 750DC | 50HP | 91# | 750x610 |

| WJ-K 850DC | 60HP | 91# | 850x610 |

| WJ-K 1000DC | 75HP | 91# | 1000x610 |

| WJ-K 850DC | 75HP | 92# | 850x900 |

| WJ-K 1000DC | 100HP | 92# | 1000x900 |

| WJ-K 1200DC | 125HP | 93# | 1200x900 |

| WJ-K 1500DC | 150HP | 93# | 1500x900 |

*Specification Subject to change without notice for improvement and modification.

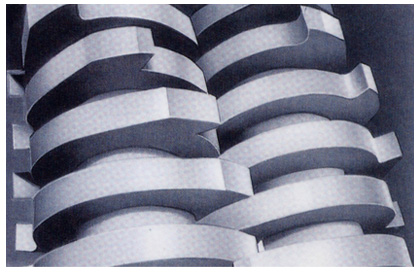

Crrushed material knife is High alloy steel, after special heat treatment, Hardness between 60°~62° hard and wear-resistant.

[ PELLETIZER FOR PLASTIC MATERIAL]

| Specification | Processed pellets( kg/h) | Motor | Weight | Dimesion(m) |

|---|---|---|---|---|

| Model | ||||

| WJ-C12 | 300 | 10 HP | 600 KGS | 1.5 x 0.7 x 1.4 |

| WJ-C15 | 500 | 20 HP | 800 KGS | 1.7 x 1 x 1.45 |

| WJ-C20 | 700 | 30 HP | 1300 KGS | 1.9 x 1.3 x 1.5 |

| WJ-C25 | 900 | 40 HP | 1650 KGS | 1.9 x 1.6 x 1.6 |

| WJ-C30 | 1100 | 50 HP | 1800 KGS | 2.2 x 1.9 x 1.65 |

*Specification Subject to change without notice for improvement and modification.

[ HYDRULIC CUTTING MACHINE ]

| Specification | Motor | Maximal cutting height | Maximal cutting width | Machine size | Machine weight |

|---|---|---|---|---|---|

| Model | |||||

| WJ-800 | 600mm | 800mm | L1200 x W600 xH2500 m/m | 1600KGS | |

| 10HP x 6P | 800mm | 1000mm | "L1400 x W700 x H3000 m/m" | 2300KGS |

*Specification Subject to change without notice for improvement and modification.